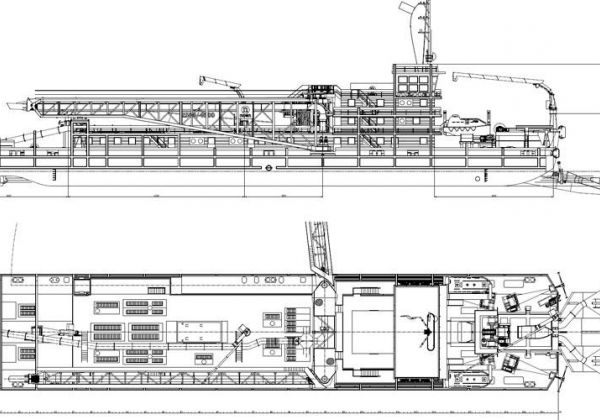

Conveying capacity: up to 4,000 m3/h

Material to be dredged: river sediment + water

Total length/width of craft: 95 m / 16 m

Width of suction inlet: 16 m

Max. suction depth: 14 m underwater

Length of discharging booms: 44 m

Draught: 2 – 2.5 m

Displacement: 2,500 t

Installed power input: 6,900 kVA

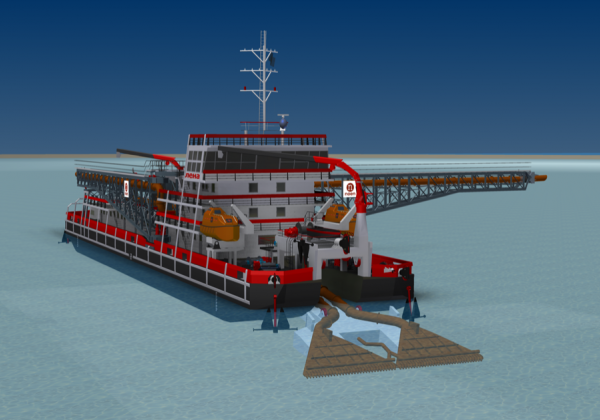

SB 2500/4000 is the self-propelled, shallow-water suction dredger with a hydraulic ripper. SB 2500/4000 provides drainage of a dredged mixture (soil, sediments,… and water):

- either through a sludge pipe mounted on slewing booms to both sides away from the craft side (to a distance over 50 m from the craft)

- or through a floating sludge pipe following a discharging mouth astern (to a distance as far as 500 m from the craft).

SB 2500/4000 above all serves for maintaining navigability of waterways. Furthermore, it can be used for execution of the following works:

- deepening of a bottom of various objects, according to approved projects resulting from data of surveys and measurements

- cleaning of river arms and channels from sediments

- building up channels

- terrain preparation of lands for house-building and industrial construction

- throwing up coffer-dams

- other water constructional works

Type of soil to be dredged – loose, light soils, such as sand, loam-sand, fine sand-gravel mixtures, clay, compact clay, loam, slightly frozen soil.

Depth of soil withdrawing is min. 1.5 m, optimum 10 m, max. 14 m under water level.

The craft is equipped among others with the following productive-technical items:

- two high-performance suction pumps for pumping a mixture of soil and water

- hydraulic ripper

- winch for lifting a boom with suction inlet for soil withdrawing

- sludge pipe mounted on side slewing booms and on deck

- set of winches for moving to another working place

The bottom deepening process control is automated to the maximum extent with the possibility of manual control. Works on the cut takes place in the semiautomatic mode making use of the program control system for the bottom deepening process and electronic cards for measurements.

The craft corresponds to a respective class of the Russian River Register (PPP): + M-ПР 2,5 (led 40)A.

The external environment parameters under considerations are as follows: assumed temperature of ambient air +35 °C at humidity of 80 % (in summer) and -10 °C at wind speed up to 25 m/s, humidity of 85 % (in winter); of water from +32 °C to -2 °C, accordingly. The carcass and the equipment shall resist temperature to -50 °C during the winter shutdown.

The craft is equipped with a residential part and background for the 28-member crew.

- 2x one-man cabin with a separate bedroom and a hygiene unit;

- 3x one-man cabin with a separate hygiene unit;

- 12x two-man cabin with a separate hygiene unit.

The craft self-sufficiency, as far as reserves of fuel, oil and provisions are concerned, is for 20 days, the self-sufficiency concerning the ecological safety conditions is also for 20 days.

The residential part is equipped among others with a mess room, kitchen, stores, sauna, radio cabin, clothes room, laundry room, drying room, common room, sickroom, workshop,…

In addition to power supply from the shore, the possibility of electricity distribution to the shore is also taken into consideration (up to power of 500 kW).

As far as prevention of environmental pollution with oil and oil products from the craft is concerned, a cistern for “bottom” waste waters and residual oils, as well as pumps for pumping water containing oil, pipes fitted with flanges corresponding to international standards, are under consideration. Containers and devices are taken into consideration for waste collection to utilize craft wastes. Furthermore, a “bottom” waste water separator and a waste water treatment plant and an incinerator with a sludge cistern are mounted on the suction dredger.

Main parameters of machine

| Weight in running order | 2590 | t |

| Conveying capacity of stacking – theoretical | 500 | m3/h |

| Conveying capacity of loading – theoretical | 500 | m3/h |

| Bulk density of material to be conveyed | 1.0 | t/m3 |

| Belt width | 1,000 | mm |

| Range of boom tilting | +14/-10 | ° |

| Slewing range of superstructure (boom) | ±105 | ° |

| Boom length | 35 | m |

| Machine height | 27.5 | m |

| Machine width | 14 | m |

| Machine length | 97 | m |

| Diameter of bucket wheel over buckets | 7,000 | mm |

| Number of buckets | 8 | pcs |

| Rail gauge | 8,500 | mm |

| Travel speed of stacker | 4-20 | m/min |

| Installed power in total | 520 | kW |

Parameters of reach

| A – Draught of dredger | 2 | m |

| B – Depth of dredging | 32 | m |

| H – Reach of discharge curve | 12 | m |