Locality: Doly Bílina

Material, output: skrývka, 12000 t/h

Width of conveyors: 2200/2000 mm

Year: 2013

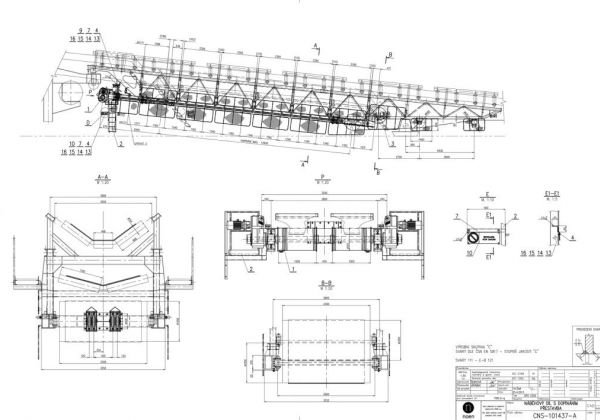

The purpose of additional tensioning in the leading part of the driving station is to extend the total tensioning path of the tensioning system for the conveyor belt.

The tensioning path of the basic tensioning mechanism in the driving station is designed for an “St” type conveyor belt. In case that a new “PA” type conveyor belt is used, the original length of a tensioning path of conveyors longer than 1,000 m is insufficient. It is necessary to use the leading part with additional tensioning.

The second tensioning loop is formed in the leading part on the conveyor belt, with a tension carriage, a reversing drum, and two transferring rollers and this loop covers the missing tensioning path.

Tensioning of the belt in the leading part is only performed, when the conveyor is stopped. After having been tensioned, the tension carriage of the additional tensioning is mechanically locked in a fixed position. Only then, the conveyor can be finally tensioned to operating parameters using the main tensioning mechanism in the driving station, thereby to secure conditions for startup and operation.

Main parameters of machine

| Belt width | 2,000 | 57 |

| Active tensioning path | 13 | m |

| Installed power input of carriage travel | 4 + 4 | kW |

| Method of transfer of forces | Rope winch | – |

| Gear ratio of gearbox | 1 : 549 | |

| Speed of tension carriage | 0.019 | m.min-1 |

| Diameter of winch drums | 600 | mm |

| Pulley transmission | 8 | – |

| Winch rope with steel core | Ø18 | ČSN024324.55 |

| Maximum motor force of carriage | 340 | kN |

| Weight | 7 | 100 kg |